In an ideal world, a perfectly lined furnace (one that lets no heat out at all) could be heated to 2000 degrees F from a flame no bigger then a candle. This hole also allows metal to be lowered into the furnace with a pair of tongs (not dropped!).Ħ) You must have a burner able to generate enough BTU’s (heat energy) to heat up the furnace to the temperature you want faster then the furnace looses heat to the outside. Therefore, you should make the lining fit well - an easy thing to do, especially with ceramic fiber and castable refractory.ĥ) There must be a hole in the top of the furnace to prevent back-pressure from building up (especially important with a venturi burner).

The danger is that a flame shooting out the side will catch something on fire or worse, burn a hole in the propane line. The amount of heat lost from a small hole or two in the furnace is nothing compared to the amount of BTU's (heat energy) the burner puts out.

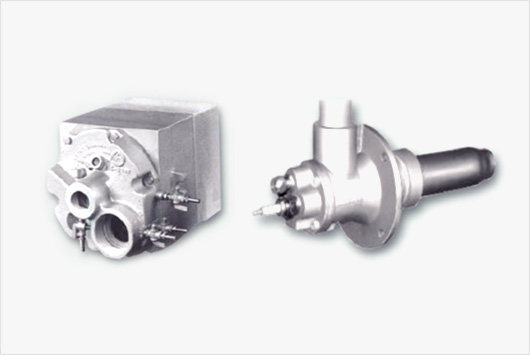

The less holes there are the better, but NOT from the point of view of melting the metal. flame shoots our from a hole or gap in the refractory) heat is lost. 2300☏ ceramic blanket can be used, but expect a shorter life.Ĥ) Every place there is a leak (i.e. You cannot use plain concrete or substitutes, this can be dangerous. The lining on my furnace should take 2700 degrees. Bronze is poured at around 2100 degrees F, but the furnace lining (especially where the flame is hitting it) gets much hotter. This distributes the heat evenly and does not overheat the side of the crucible.ģ) The refractory you use must be able to take the heat within the furnace. The body could be made of screen and it will work the same, it’s only purpose is to hold the refractory in place.Ģ) The burner should come in at an angle (see diagram #1) so the flame forms a vortex or whirlwind around the crucible. The steel shell does not hold in any heat, it is the refractory that holds in the heat (the lining inside the furnace shell). If you follow certain basic principles the furnace will work just fine.ġ) A furnace body is mainly an enclosure to hold the heat that the burner puts out. Think of this as a recipe for building the furnace, there are many variations you may use depending on our skills, the tools in your shop and availability of materials. The pictures here are from a class I did where we built 3 furnaces. This furnace is able to melt 25 lbs of bronze in about 30 minutes. If you have questions or comments please contact me at: love to hear from you!Ĭapable fo melting up to 30 lbs of Bronze Uses a party helium tank (the same size as a 5 gal propane tank).Melts 30 lbs of bronze in 30-40 minutes.This is exactly the same furnace I use in my own studio. The furnace we built is a small helium tank furnace, capable of melting 30 lbs of bronze in about 40 minutes. Thus it is written as a "How To" article, meant to be combined with the seminar, which includes discussions on safety and proper use of the furnace.

I took pictures during the seminar and combined it with pics of my own furnace to create this article with the intent of using it at other seminars. I was invited to teach a seminar on furnace building for a foundry class at El Camino College. The main difference is a smaller sized freon tank rather then the 5 gal propane tank. I'm also a blade-smith and have made several forges using similar materials and techniques as this furnace. To start, take a look at my safety page and Furnace Lighting Procedures. Dangers inculde propane explosions, severe burns, carbon monoxide poisoning to name a few. Building and operating a furnace without proper knowledge and a good dose of common sense can lead to injury or death! Read up on safety procedures before using this or any furnace. Should you attempt to build a furnace like this one, I am not responsible for ommissions, mistakes, or errors that may lead to injury or death. I am putting it here for educational purposes only. This article is an account of constructing a small bronze casting furnace. Project #1: Direct Wax Sculpture, Ceramic Shell Casting.Project #2: Sandcasting a Bas Relief Bronze Plaque.

0 kommentar(er)

0 kommentar(er)